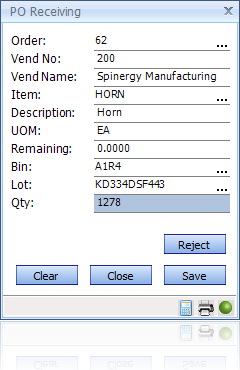

PO Receiving

Typically, PO Receiving is done on a mobile device so that materials can be scanned from the receiving truck (the first touch point in the organization) and remain mobile in the receiving dock. As Items are scanned, the open PO’s, line items and other item attributes (Serial/Lot Information, etc.) are scanned or entered. The transaction is then instantly recorded and material information is available.

Purchase Orders can quickly be scanned and validated to identify the quantity to receive, Bin and Serial/Lot information.

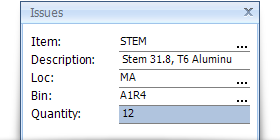

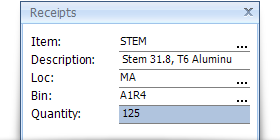

Put Away

Take maximum advantage of the warehouse logistics benefits of Bins.

- Binned items can be received to a put-away bin or bin on the shelf.

- Receiving inspection items are received to the appropriate location.

- Shop Floor outside processes are supported and the corresponding Shop Floor order is updated when PO is received.

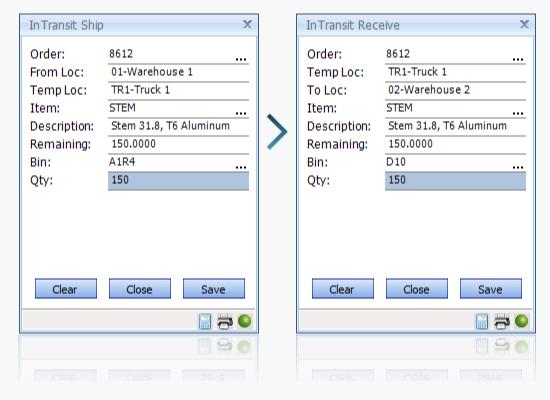

InTransit Inventory Management

WiSys In Transit Inventory lets you transfer inventory from one location to another by using a temporary location to store the items while in transit. This temporary location corresponds to the truck, ship, train, etc. that contains the inventory en route. It is assumed that the temporary location is a non-binned location.

How does it work?

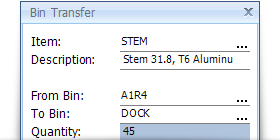

Setup the InTransit order and flag the order as approved. The users on the floor can then use mobile handheld devices to ship and receive material between locations. Validate InTransit order and validate and ship each item on the order. Bin and Serial/Lot information is also validated and transferred to the temporary location. At the destination location, receive each item on the order. Bin and Serial/Lot information is also validated and transferred to the final destination.